Swallowing difficulties (dysphagia) can affect a wide range of individuals, including infants and the elderly as well as neurological, cancer or post-surgery patients. To promote better patient compliance, new tablet formulations such as minitablets, orodispersible tablets (ODTs) and orodispersible minitablets (ODMTs) have been developed. A study shows that direct compression-grade isomalt (galenIQTM 721) is a good choice of filler-binder for the production of these dosage forms.

Minitablets

Minitablets are generally accepted to be compressed tablets with a diameter of 2–3 mm (Figure 1). They can be manufactured on regular rotary tablet presses with the use of appropriate multi-tip punches (Figure 2). Owing to their small size, production can present challenges with respect to blend uniformity, flow properties and mass uniformity. The choice of filler-binder is therefore important: its powder and compression characteristics must promote both high content uniformity and relatively high tablet hardness at low compression forces.

Figure 1: Minitablets are generally accepted to be compressed tablets with a diameter of 2–3 mm

Figure 2: Minitablets are manufactured on regular rotary tablet presses using multi-tip punches (centre).

Orodispersible tablets and orodispersible minitablets

Orodispersible tablets (ODTs) disintegrate or dissolve rapidly in the mouth without the use of water or chewing. They are particularly advantageous for paediatric and geriatric populations. When delivered in minitablet form, the disintegration time can be reduced significantly. The use of ODMTs in paediatric patients has gained importance in recent years; one study investigated the feasibility of isomalt, which is known for its pleasant sensory properties, as a filler-binder.

In this study, the active pharmaceutical ingredient (API) was enalapril maleate, an angiotensin converting enzyme (ACE) inhibitor used to treat conditions including heart failure, high blood pressure and hypertensive emergency. It is listed as an essential medicine, emphasizing the need for a suitable dosage therapy for children.

Isomalt is a polyol derived from sucrose that comprises two mutually diastereomeric disaccharide alcohols: 6-O-α-D-glucopyranoside-D-sorbitol (GPS) and 1-O-α-D-glucopyranoside-D-mannitol-dihydrate (GPM). Agglomerated isomalt is widely used as a filler-binder in direct compression tableting owing to its good compressibility, flowability, and workability.

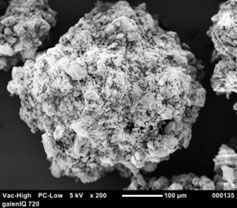

The ratio of GPS to GPM can influence isomalt’s water solubility. At a ratio of 1:1, it has an aqueous solubility of 25 g in 100 g at 20 °C; at a ratio of 3:1 GPS to GPM, it has an aqueous solubility of 42 g (Table I). Figure 3 shows the porous structure and spherical particle shape of each type — characteristics that promote good blending and high content uniformity in powder mixtures. To develop the ODMTs for this study, the higher solubility agglomerate form (3:1 GPS:GPM) was used.

Table I: Typical agglomerated isomalt characteristics

| 1:1 GPS:GPM | 3:1 GPS:GPM | |

| Solubility in water at 20 °C (g/100 g) | 25 | 42 |

| Bulk density (g/L) | 400 | 400 |

| Tapped density (g/L) | 480 | 480 |

| Angle of repose (°) | 38 | 37 |

Figure 3: Scanning electron micrograph images of agglomerated isomalt

(Philips XL-30 FEG)

1:1 GPS:GPM

1:1 GPS:GPM

3:1 GPS:GPM

To produce ODMTs of the required dosage strength (1 mg) for this study, enalapril maleate (16%), 3:1 GPS:GPM agglomerated isomalt (79%) and cross-linked polyvinylpyrrolidone (4%) as a superdisintegrant were mixed together in a Turbula mixer for 15 minutes. Magnesium stearate (1%) as lubricant was then added and the formulation was mixed for an additional 2 minutes. This blend was then compressed on a rotary tablet press into 6.25 mg round biconvex tablets using 2 mm 19-tip punches and a compression force of 5–6 kN (71–85 MPa).

Study Summary

The study evaluated the characteristics and stability of enalapril maleate ODMTs. Various parameters were assessed, including disintegration time, dissolution kinetics, mass variation, content uniformity, acceptance value and stability attributes. Disintegration times were measured using a method involving a Plexiglas cylinder with a mesh sieve placed in a conventional disintegration apparatus. Six ODMTs were tested at 37 ± 2 °C in demineralized water.

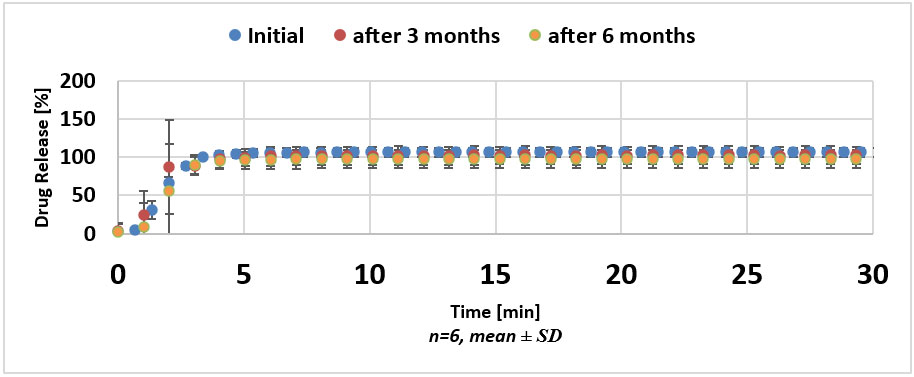

Dissolution tests were conducted in a basket apparatus using a phosphate buffer (pH 6.8) stirred at 50 rpm. API release was measured at 208 nm wavelength according to the USP 39-NF 34 monograph. Mass variation was assessed based on Ph.Eur. 2.9.5. Twenty minitablets were weighed on an analytical balance.

Content uniformity: High-performance liquid chromatography with UV-VIS coupling was employed to determine content uniformity, following Thabet and Breitkreutz’s method.[1]

Acceptance value (AV) Determination: Enalapril maleate AV was determined using Ph.Eur. 2.9.40. Minitablets were dissolved in a 50/50 acetonitrile/phosphate buffer solution, filtered and analyzed using high-performance liquid chromatography.

Stability testing: Tensile strength, API release and disintegration time were measured for ODMTs stored under different conditions. Ambient storage and accelerated stability conditions (40 °C/75% relative humidity) were used, following WHO guidelines.[2] Measurements were taken at different intervals. The tablet properties are shown in Table II. The dissolution measurements are shown in Figure 4.

Table II: Tablet properties

| Property | Method | Initial | After 6 months |

| Hardness (N) | Ph.Eur. 2.9.8 | 4 ± 1 | 4 ± 1 |

| Disintegration time (s) | Modified method Ph.Eur. 2.9.1 | 9 ± 2 | 7 ± 3 |

| Acceptance value (AV) | Ph.Eur. 2.9.40 | 15 | |

| Mass | Ph.Eur. 2.9.5 | Conforms |

Figure 4: Dissolution of enalapril maleate ODMTs

Results

- ODMTs showed sufficient hardness at low compression forces.

- Content uniformity fulfilled the specified acceptance value (AV ≤ 15) and complied with Ph.Eur. requirements.

- Disintegration times changed slightly during stability testing but met both Ph.Eur. (180 s) and FDA (30 s) disintegration limits.

The study confirmed the successful production of low-dose enalapril maleate orodispersible minitablets using agglomerated isomalt as a filler-binder through direct compression. The recommended filler-binder, galenIQTM 721, enables the convenient manufacturing of orodispersible minitablets.